AC130dq with Double Circuits Stainless Steel Plates Evaporator Zl130 Series

YOJO Heat Exchanger Advantage: High Efficiency The embossed pattern of the YOJO's special heat transfer plates promotes

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | ZL130 |

| Max Flow(L) | 42m3/H |

| Weight(Kg) | 6.5+0.37n |

| Structure | Plate Heat Exchanger |

| Voltage | 220V |

| Place of Origin | Jiangsu, China (Mainland) |

| Warranty | 1 Year |

| Model Number | Zl130 |

| Transport Package | Plate Heat Exchanger |

| Specification | plate heat exchanger |

| Trademark | Yuan Zhuo |

| Origin | Plate Heat Exchanger |

| HS Code | 8419500090 |

| Production Capacity | Plate Heat Exchanger |

Product Description

YOJO Heat Exchanger Advantage:High Efficiency

The embossed pattern of the YOJO's special heat transfer plates promotes high turbulence at low fluid velocities. The high turbulence results in very high heat transfer coefficients.

Compact Size

YOJO's brazed heat exchanger can be anywhere from 50% to 80% smaller than other types of heat exchangers. It requires less floor space due to the high thermal efficiency of the stainless steel. The plates are brazed together at high temperatures, allowing the heat exchanger to be compact, leak tight, and rugged.

Close Approach Temperatures

Close-approach temperatures of 1-2°F (0.5-1.0°C) are possible because of true counter flow and high heat transfer efficiency of the plates. This is an important factor in regeneration and heat recovery processes.

High Temperature and Pressure Ratings

YOJO's Brazed Plate Heat Exchanger maximum working pressures from 300 psi to 650 psi, and temperature ratings of 350°F.

Model | A (mm) | B (mm) | C (mm) | D (mm) | thickness (mm) | weight (mm) | Stagnant fluid volume (L) | Design pressure (Mpa) | Max fluid (L) |

|---|---|---|---|---|---|---|---|---|---|

ZL14 | 76 | 42 | 172 | 206 | 9+2.3N | 0.6+0.056N | 0.010(N-2) | 1/3/4.5 | 8m3/h |

ZL18 | 95 | 50 | 165 | 210 | 9+3.1N | 0.3+0.06N | 0.010(N-2) | 1 | 8m3/h |

ZL20B | 78 | 42 | 282 | 318 | 9+2.3N | 0.9+0.088N | 0.018(N-2) | 3/4.5 | 8m3/h |

ZL26 | 111 | 50 | 250 | 310 | 10+2.36N | 1.3+0.12N | 0.025(N-2) | 3/4.5 | 18m3/h |

ZL30 | 124 | 70 | 250 | 304 | 13+2.4N | 2.2+0.146N | 0.032(N-2) | 3/4.5 | 18m3/h |

ZL52A | 111 | 50 | 466 | 525 | 10+2.35N | 1.9+0.215N | 0.047(N-2) | 3/4.5 | 18m3/h |

ZL52B | 111 | 50 | 466 | 525 | 10+2.35N | 1.9+0.213N | 0.047(N-2) | 3/4.5 | 18m3/h |

ZL62B | 119 | 63 | 470 | 526 | 10+2.35N | 2.4+0.223N | 0.051(N-2) | 3/4.5 | 18m3/h |

ZL95A | 191 | 92 | 519 | 616 | 11+2.76N | 6+0.415N | 0.125(N-2) | 3/4.5 | 42m3/h |

ZL95B | 191 | 92 | 519 | 616 | 11+2.76N | 6+0.413N | 0.125(N-2) | 3/4.5 | 42m3/h |

ZL120A | 246 | 174 | 456 | 528 | 13+2.36N | 7+0.472N | 0.98(N-2) | 3/4.5 | 42m3/h |

ZL120B | 246 | 174 | 456 | 528 | 13+2.36N | 7+0.472N | 0.98 (N-2) | 3/4.5 | 42m3/h |

ZL200A | 321 | 188 | 603 | 738 | 9+1.58N | 13+0.74N | 0.22(N-2) | 1.5/2.1/3 | 100m3/h |

ZL200B | 321 | 188 | 603 | 738 | 13+2.7N | 13+0.73N | 0.22(N-2) | 1.5/2.1/3 | 100m3/h |

High efficiency heat exchanger

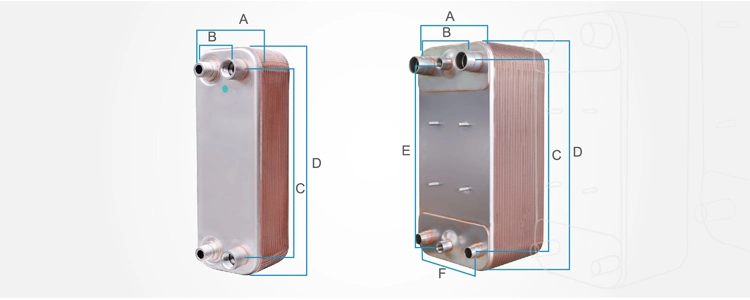

Our ZL20, ZL62 series, ZL130, ZL250 are specifically developed for R410A refrigerant, which is ideal alternative of R22. R410A efficient heat exchanger is not only resistant to high pressure, but also with less refrigerant to achieve the same cooling effect. ZL20 and ZL62 are unilateral flow. ZL130 and ZL250 are diagonal flow. They can work from the power range of 1KW to 250KW.

Model | A (mm) | B (mm) | C (mm) | D (mm) | Thickness (mm) | Weight (mm) | Stagnant fluid volume (L) | Design pressure (Mpa) | Max fluid (L) |

|---|---|---|---|---|---|---|---|---|---|

ZL20A | 86 | 40 | 269 | 315 | 9+1.58N | 1+0.084N | 0.018(N-2) | 3/4.5 | 8m3/h |

ZL62A | 119 | 63 | 470 | 526 | 10+2.35N | 2.4+0.225N | 0.051(N-2) | 3/4.5 | 18m3/h |

Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | Thickness (mm) | Weight (mm) | Stagnant fluid volume (L) | Design pressure (Mpa) | Max fluid (L) |

|---|---|---|---|---|---|---|---|---|---|---|---|

ZL130 | 247 | 161 | 495 | 414 | 369 | 172 | 10+2.15N | 4+0.424N | 0.080(N-2) | 3/4.5 | 42m3/h |

ZL250 | 322 | 205.2 | 739 | 631.7 | 568 | 224.4 | 13+2.7N | 16+0.711N | 0.22(N-2) | 3/4.5 | 100m3/h |

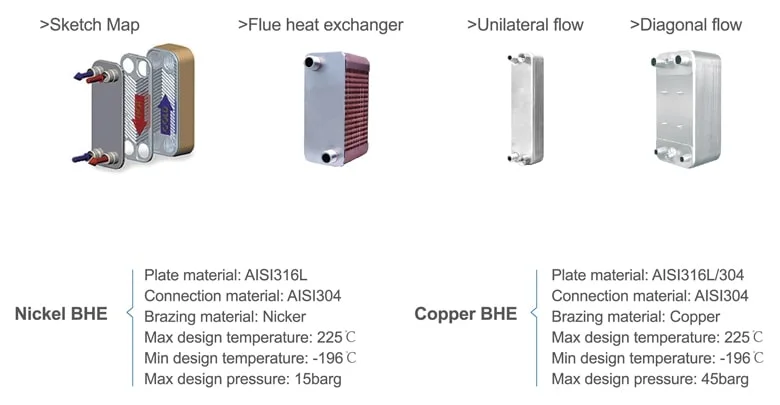

Aircross

Aircross is a cross flow plate heat exchanger vacuume with pure copper or nickel based material. The top and bottom plates including side A connections are brazed to the plate package. This model can be asymmentrical for 1) applications with a smaller flow rate at high pressure on the one side ( Side A), and a larger flow rate at with lower pressure on the other ( Side B): different sizes for the connections In and Out, different channel lengths, different channel areas and volumes; 2) applications with a constant and defined gas flow on one side and medium with higher density on the other side. Normally YOJO-AirCross is used with a liquid on side A and gas on side B.

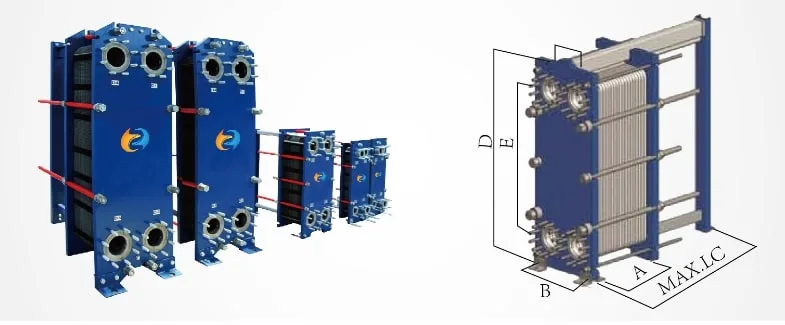

Gasket Plate Heat Exchanger

Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | MAX. LC (mm) | Connection (mm) | Exchange area (m2) | Max. Number of plates | Max. volume flow (m3/h) | Design Pressure (Mpa) |

|---|---|---|---|---|---|---|---|---|---|---|---|

B30B | N(2.5+X) | 180 | 60 | 480 | 357 | 500 | 32 | 0.032 | 95 | 18 | 1.6 |

S60H | N(4+X) | 400 | 203 | 704 | 380 | 1200 | 65 | 0.086 | 147 | 50 | 1.6 |

B60B/B60H | N(2.0+X) N(3.0+X) | 320 | 140 | 920 | 640 | 1200 | 50 | 0.15 | 250/203 | 36 | 1.6 |

K60B/K60H | N(2.0+X) N(3.0+X) | 320 | 140 | 950 | 689 | 1200 | 50 | 0.2 | 250/203 | 36 | 1.6 |

B100B/B100H | N(2.55+X) N(3.95+X) | 470 | 225 | 1069 | 719 | 1600 | 100 | 0.25 | 278/180 | 140 | 1.0/1.6/2.5 |

K100B/K100H | N(2.55+X) /N(3.95+X) | 470 | 225 | 1099 | 763 | 1600 | 100 | 0.3 | 278/180 | 140 | 1.0/1.6/2.5 |

S200H | N(4+X) | 800 | 363 | 1405 | 698 | 3000 | 200 | 0.3 | 400 | 600 | 1.6 |

L100B | N(2+X) | 480 | 225 | 1888 | 1338 | 3000 | 100 | 0.5 | 400 | 140 | 1.0 |

K150H | N(3.95+X) | 610 | 298 | 1616 | 1095 | 3000 | 150 | 0.5 | 600 | 360 | 1.0/1.6/2.5 |

B150B/B150H | N(2.5+x) N(3.95+X) | 610 | 298 | 1815 | 1294 | 3000 | 150 | 0.65 | 600 | 360 | 1.0/1.6/2.5 |

B200H | N(4+X) | 780 | 353 | 2260 | 1478 | 3000 | 200 | 0.85 | 400 | 600 | 1.0/1.6 |

B250B | N(2.5+X) | 920 | 439 | 2895 | 1939 | 3000 | 250 | 1.5 | 500 | 750 | 1.0/1.6/2.5 |

B350B | N(3.3+X) | 1150 | 596 | 2882 | 1842 | 4800 | 350 | 1.85 | 700 | 997 | 1.0/1.6 |

Product Material

Frame plate: Carbon steel/Stainless

Nozzles: Carbon steel/Stainless

Metal lined: Stainless steel,Titanium

Gasket:NBR ( Nitrile ), EPDM, F26, FTP etc.

Plate: Stainless steel 316L/304/Titanium/ti-Pd SMO254/Ni/HASTELLOY ( C276, C22)

Gasket fastening solutions: Clip-on gasket/Tape-on gasket

| Plate material | suitable fluid |

|---|---|

| Stainless steel(SUS304,316L etc.) | pure water, river water, edible salt water, mineral oil |

| Ti,ti-pd | brine,sea water, salt water, |

| SMO254 | dilute sulphuric acid,Salt water solution,Inorganic aqueous solution |

| Ni | High temperature,High concentration of caustic soda |

| HASTELLOY(C276,C22) | concentrated sulfuric acid,hydrochloric acid,phosphoric acid |

| Main body gasket | operating temperature(ºC) | suitable fluid |

|---|---|---|

| NBR | -15~+135 | water,sea water,mineral salt,brine |

| EPDM | -25~+180 | Hot water,vapour,acid,base |

| F26 | -25~+230 | acid,base,fluid |

| FTP | 0~+160 | Concentrated acid,base,high temperature oil,vapour |

Application:

Heating systems

Tap water heating

Printing and dying industry

Ship building

Swimming pool heating

Cooling system

Central cooling

District cooling

YOJO Workshop

Related Products

-

![Anti]()

Anti

-

![York 210 Car Air Conditioning AC Compressor for Freightliner]()

York 210 Car Air Conditioning AC Compressor for Freightliner

-

![Auto Parts for Jeep Cherokee 709 Rear Cover Air Conditioning Parts AC Compressor]()

Auto Parts for Jeep Cherokee 709 Rear Cover Air Conditioning Parts AC Compressor

-

![on Sale Aluminium Aluminum Coil with 1100 3003 8011 A3003 H14 6061 7075 Trim Channel Letter Gutter Evaporator Corrosion Wood Grain Al Colors Coated in Stock]()

on Sale Aluminium Aluminum Coil with 1100 3003 8011 A3003 H14 6061 7075 Trim Channel Letter Gutter Evaporator Corrosion Wood Grain Al Colors Coated in Stock